Global trends and technologies that emerge and develop with an enormous pace impact the Supply Chain heavily. Technologies as blockchain, Artificial Intelligence (AI) and Internet of Things (IoT) are on the rise, fueled with an increasingly complex and dynamic business environment (e.g. US-China trade war, the Amazon effect). This forces companies to rethink their Supply Chain towards a more repetitive and pro-active attitude. Here Center of Excellences powered by strong analytical tools can add significant value!

Typically a COE is about bringing together knowledge, expertise and resources within a certain field. The goal is to achieve and sustain the best-in-class performance and value to the Customer. When you think about building this it involves an organization, processes, people and analytical tools.

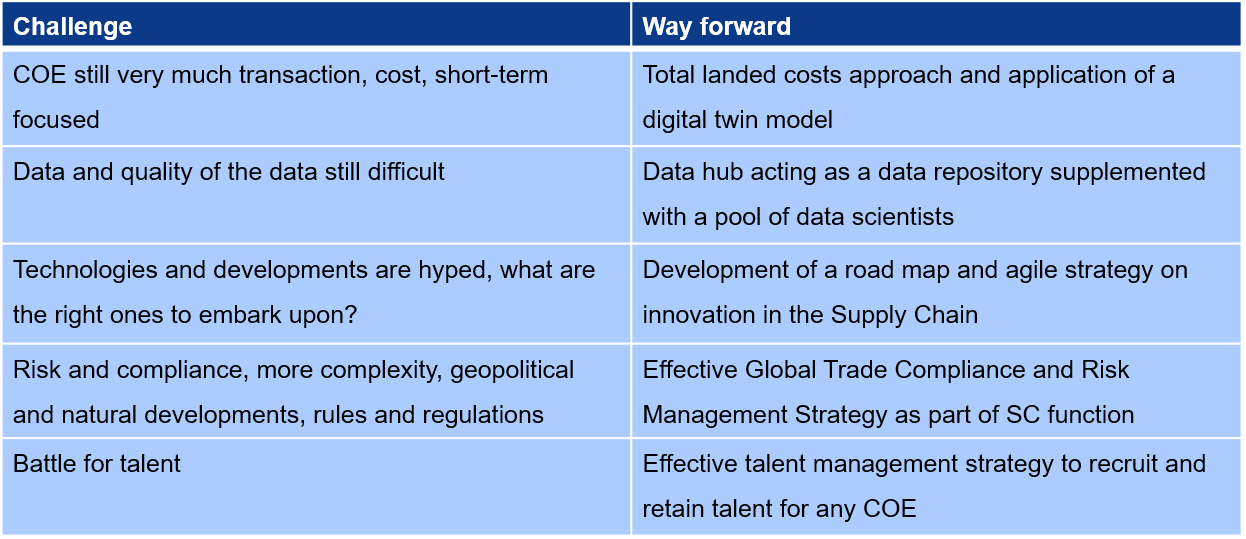

However, when we put this in the Supply Chain environment it involves a lot more than this, as there are various challenges and developments a company is coping with. The top 5 challenges and a way forward are depicted in the table below.

Given all of these challenges, these are some key questions to consider on a COE journey:

Many analytic capabilities can be included in an Center of Excellence, hinging on the questions asked by leadership. Typically we see analytics services in the fields of transportation, network optimization, risk (& compliance), cost to serve and inventory & planning. The analytics always need to be fueled with the right data. Are you able to retrieve information with the right level of detail and quality in a simple and repetitive way? This is a big challenge for many companies still today. There are various tools available on the market place dependent on the type of result you would like to achieve. For a data cube you typically see Qlikview or Tableau, for network studies Llamasoft is commonly used, for inventory & planning more and more specialized tools are introduced.

A new concept is the digital twin concept, which is a digital replica of your Supply Chain to provide answers to senior leadership within hours not weeks. Think about tariff hikes, port strikes, risks that cannot be handled with by a business continuity planning process. Key is to have the right data available, not within 6 months but at your fingertips. Not only for now, but also towards alternative future scenario’s. A new trend is to use Supply Chain Network Design capabilities for Sales & Operations planning, supporting a true Integrated Business Plan.

The potential of a technology depends heavily on the type of industry, the discipline of the Supply Chain and the type of problem or opportunity at hand. Blockchain is well established in the diamond industry given the uniqueness of the product, but also trending in the pharmaceutical market given the various compliance and quality requirements from the markets. AI is an interesting area especially at this stage in the inventory and demand planning. 3D printing is very interesting in the spare parts industry, but you also the FMCG and Hi-tech sector more and more making use of this technology. This is especially interesting when you have short life cycles and many new product introduction for which you need to act fast and have high uncertainty of how the demand is going to develop.

How to implement those technologies? Start looking for customer and internal opportunities where innovation can bring benefits, hereby considering the whole Supply Chain and other industries for inspiration. Key is here to look beyond the myth, and take a step by step approach. Start small, pilot and make sure you are able to learn and scale fast.

This leads to the following conclusions:

Learn more?

Request the presentation COE powered by advanced analytics below.