Covid-19 has exposed the vulnerabilities of global complex supply chains. Many companies are faced with a lack of end-to-end visibility. Do you stay in the dark or develop a control tower?

Whereas in the past companies experienced risks like flooding, hurricanes, strikes and collapse of providers (i.e. Hanjin), the call for end to end visibility was not answered by senior leadership. A recent BCI survey conducted in April 2020 in the middle of the pandemic indicated that over 85 % of the companies did not have a control tower in place or to a very limited extend (n=65). When asked whether Covid-19 had accelerated the urgency and need for control towers more than 70% of the respondents clearly indicated the urgency to have a control tower in place to have visibility and be in control.

Control towers have been around for more than a decade and have various appearances. From a consumer perspective buying online and having instant visibility on inventory on hand, order status, in transit times and even the ability to route the shipment when in flight, it is rather strange that multinational companies have not yet been able to adopt the concept of control towers yet. Do we like to be in the dark and not having the ability to see? Given the complexity of global supply chains and multi-tier vendors, companies need to re-consider taking complexity out of their global supply chain or embrace complexity but having the right mechanisms in place to be in control and manage the supply chains better. Here is where control towers play a crucial role.

Companies that have a control tower in place typically focus on either intercompany or downstream from the DC to the Customer. Where to start and where a control tower adds value to you depends on your set up and complexity level of your supply chain. Covid-19 has put emphasis on the need for both upstream as well as downstream management. Upstream given the supply shortages and interdependencies between components and subassemblies and the geographic sourcing base across the globe. The key is to understand and the ability to dig into your Bill of Material to understand your tier 1 supplier base and beyond.

Visibility is great, but visibility by itself provides limited value especially when your supply chain is navigating through stable waters. Ultimately a control tower needs to enable faster and better decision making ability for the brand owner. Control is key! Control in terms of data, metrics, costs, inventories, transit times and being able to manage by exception.

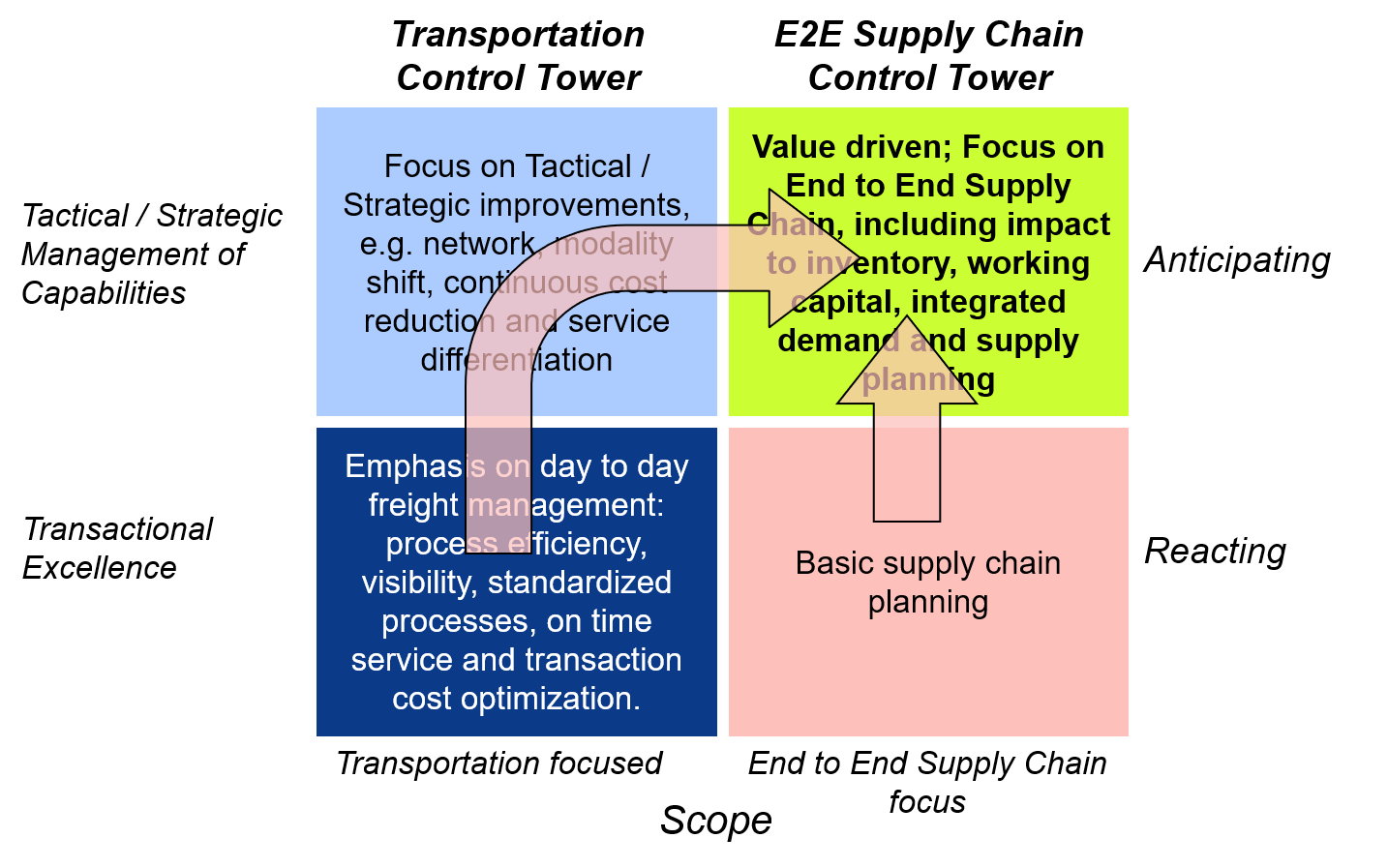

Traditional Control Towers focus on managing freight are applied for instance in the automotive industry to allow Just In Time and Just In Sequence concepts to be successful. The scope of Freight Control Towers is expanding and more and more End-2-End Supply Chain Control towers are put in place. The key difference with traditional Control Towers is an increased focus on tactical/strategic capabilities and covering more functional elements of the supply chain, such as supply chain redesign, end-to-end inventory planning, global trade management, and integrated demand & supply planning.

Source: BCI Global, 2020

Examples of companies that made the transition towards an End-to-End Control Tower are Samsung, Apple, Amazon, Lenovo, Merck, Walmart and Unilever. These companies have banked the benefits including improved customer service, lower inventory and operational costs.

The benefits of control tower include increased supply chain visibility, improved reliability and service levels, reduced costs and continuous improvement. Next to these benefits the creation of a uniform dataset (Single Point of Truth) is growing in importance.

Successful Control Tower operations also deliver benefits such:

An End-to-End Control Tower can also be your base for your Supply Chain Center of Excellence and your stepstone to digitization further your supply chain.

BCI has developed a Control Tower Maturity Matrix which covers Strategic, Tactical and Operational processes and best practices. This Maturity Matrix supports benchmarking and can identify a path forward.

Further reading – download the BCI webinar End to end control towers or the Risk & Resilience framework.