Location selection for manufacturing plant

One of your key strategic decisions is selecting the right location for your new manufacturing plant. You are making new investments in land, buildings, equipment and talent for the long term. As the global business environment in which you need to make a location decision is becoming more uncertain every day, it is crucial to make a robust and future proof selection of a location.

Our team of experts has extensive experience in this field, with a deep understanding of global markets and local situations. We provide you with comprehensive location analyses and data and experience driven recommendations to help you identify the best locations for your business. We do this around the globe, including EMEA, North America and LATAM, China and Asia-Pacific.

In the current global environment, uncertainty is a given. Geopolitical turmoil, technological developments, labor market challenges, tax climate changes to name a few, are having a huge impact on cost effectiveness, quality of the business environment and the risk profile of your current production locations. We support you with a thorough fact-based location strategy and site selection analytics, no matter whether your project has a global scope or is focused on EMEA, North America, LATAM, China or Asia-Pacific.

We can support in two phases of your new manufacturing location selection process:

Scenario analysis

In this strategic phase we support you with defining and analyzing meaningful location scenarios in order to answer questions such as: can we expand production capacity at our current location(s) or should we set up a new location? How many new production locations do we need? In what geographical area should we start selecting a new manufacturing location and site?

In the scenario definition and analyses we take amongst others the following factors into account:

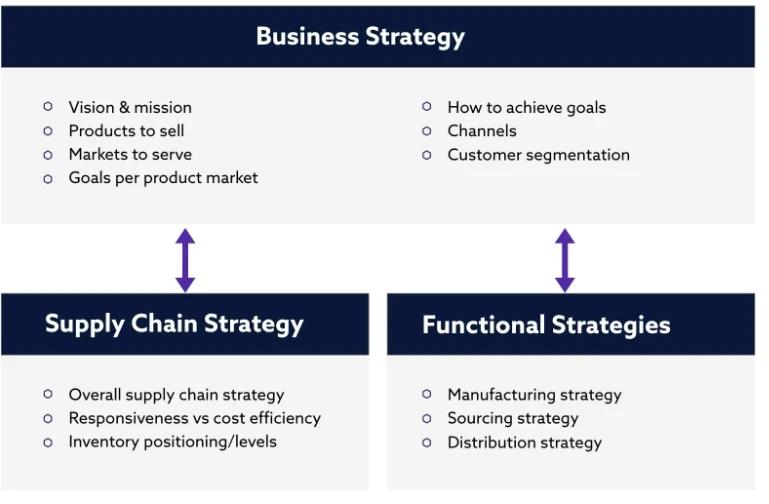

- Your company’s overall business strategy

- Future business projections

- External factors (e.g. economy, geopolitical, legal and regulatory, climate, new production technologies)

Based on a well-based quantitative and qualitative comparison of the different location scenarios the preferred scenario is selected and the next steps for your company are defined. These next steps may include a detailed location & site selection process.

Location & Site Selection

In order to select the optimal location for your company’s new manufacturing site we execute a step-wise filtering process. The filtering from longlist to shortlist and final optimal manufacturing location is very much fact-based and focuses on comparing locations from a Cost, Quality of the Business Environment and Risk perspective. Once the shortlist of candidate locations is defined we start the fieldwork activities: conducting fieldwork visits to the top locations in order to validate and enrich all desk research findings with actual insights from the field.

In addition to our location strategy and site selection projects we also help companies in:

- detailed labor market analyses, applying our proven IDEAL methodology (In-Depth Assessment of Labor Markets) to answer your questions regarding the feasibility of recruiting and retaining your staff in current and / or new locations

- detailed location risk assessments, using our in-house developed IRAM risk framework (Integral Risk Assessment Method), to assess the risk level of your company’s current (and potential future) locations on 46 different location risk elements

Our approach is a step-wise filtering process. After having detailed the specific profile of your manufacturing investment project and the key location drivers, a first assessment of a longlist of locations takes place based on a set of critical location factors. Based on this assessment a shorter list of promising locations is selected which are analyzed using a detailed listing of cost, quality of the business environment and risk factors. Following from that last desk research step, the most promising locations are selected for fieldwork visits. During the fieldwork detailed discussions are held with local authorities, economic development agencies, recruitment experts, real estate companies, peer companies and so on in order to come to the selection of the optimal new production location.

Location & site selection filtering process for a new manufacturing plant

You probably have already some locations in mind at the start of your location selection process. But be prepared to be surprised, as we take not just the sites you come up with into consideration, but also potential locations that have a good score based on the criteria agreed upon. And that is the first step: in consultation with you we select the right criteria and the weights of those criteria for your manufacturing site selection.

In the matrix the costs of all candidate locations are presented on the vertical axis with the lowest cost on top and the highest at the bottom. The horizontal axis shows the weighted average quality scores per location and by color coding the risk profile of each location is indicated.

Example of what a site selection outcome looks like

Based on a matrix like this your company’s top management can make a well-balanced decision on what is the perfect location for your future new manufacturing facility: should we go for the best Cost/Quality balance? How important are the location costs in our decision? Do we see any critical risk elements that drive us towards or away from certain locations?

The site selection criteria and their weights may vary, depending on your business strategy and the type of production activity planned at the new location. Location factors or relative weightings may also differ per geographical region. For example investment incentives and grants for certain projects are more of a driver in North America than in Europe and natural disaster risks are typically weighted as more important in Asia-Pacific than in Europe.

Site selection factors

In location and site selection for new manufacturing plants many factors may play a role, so your location and site selection advise is based on three types of factors:

- Costs - All relevant factors that can be translated into money such as land, real estate, labor, logistics costs, taxes, etc. minus the investment incentives, grants, tax credits and tax exemptions offered in the different locations

- Quality of the business environment - Factors that cannot be translated directly into currencies, but have still a direct effect on the performance of the new operations. Think of availability of labor, accessibility, supplier availability, availability and reliability of utilities, customs regulations, ease of doing business and cultural fit

- Risks - All external business disruption risk factors that you cannot influence, but that still may have a substantial impact on your future operations such as inflation risk, currency exchange rate risk, transparency risk, natural disaster risk, etc.

The realization of a new production location comes with significant investments and internal changes. The investments are done for a long period of time and therefore the impact of the new location should also contribute positively for a longer period of time. In other words: in case of a wrong location decision the negative implications will also have a negative impact for a long period (e.g. higher costs, issues in finding the right labor, regulatory issues).

Investment incentives and tax reduction measures are attractive in certain countries/States/regions in Europe, the US, Mexico/Latin America, China, Asia. Especially for new production facilities with a large number of workers the total financial packages can be (very) interesting for you.

Geographical granularity

In our approach we typically start at the level of regions within countries rather than comparing countries at a national level. This is because for many important location factors the differences between regions in the same country can be significant. This is for example the case for factors like labor costs, labor availability, real estate availability, natural disaster risks and many others.

Illustration of in-country differences based on recent BCI projects

Site selection criteria for your manufacturing plant

You might have a variety of reasons for starting the site selection process for your new manufacturing plant: cost reduction, expansion of capacity to facilitate business growth, the entry of new markets, tapping into new labor pools, rationalization after a merger or acquisition, risk mitigation and coping with geopolitical developments, etc.

In the location selection for a new manufacturing plant a key driver is the talent factor for the new plant: is it a highly automated plant where only a limited number of high skilled operators will be working or is it a labor-intensive operation with hundreds of lower skilled workers? These varying profiles have a large impact on the importance of factors such as labor costs, labor availability, labor market competition, flexibility of working hours, etc. The realization of a new production plant comes with significant investments (or leases). In addition, next to proximity of key markets, transportation costs, and especially now, energy security and energy and other utility costs can be of key importance in selecting the right location for your plant!

Detailed labor market analysis

We conduct detailed labor market analyses, helping you to determine to what extent you can still recruit and retain the right amount and quality of talent in your current and / or potential new locations. In this approach we apply quantitative labor market analysis on supply of and demand for talent, conducting 5 to 10 year forecasts, and enrich that with in-depth qualitative analysis by gathering information from experts in the local labor market, assessing experiences of other companies in the same labor pool, assessing primary and secondary employment packages and so on.

05 December 2024

04 December 2024

04 December 2024

15 December 2023

28 September 2023

11 July 2023

10 May 2023

24 March 2022

17 February 2022

25 May 2021

11 December 2025

01 July 2025

25 June 2025

25 June 2025