04 December 2024

Coping with Rising Trade Tariffs

Trade restrictions are on the rise all over the world. President Trump will probably give a push to higher import tariffs, provoking retaliation measures of other trading blocs like Europe and Japan.

Trade restrictions can be added to the list of challenges worldwide operating companies have to deal with: geopolitical risks, fast technological developments, economic uncertainty, labor market tightness, more stringent regulations. The common characteristic is that a company can not influence these developments itself, but that they are more and more driving changes of the manufacturing footprint and distribution network in the various regions where companies operate.

President Donald Trump has announced to implement import-tariffs of 10%, 20% or 25% for all goods from all countries in the world. Taiwanese chips, French wine, German cars, Japanese precision machines, Latin American food, they all are part of Trump’s intention. It looks like that even neighboring trade partners like Mexico and Canada have to face high import tariffs in order to restrict illegal immigrants and export of drugs to the US.

Risk Assessment

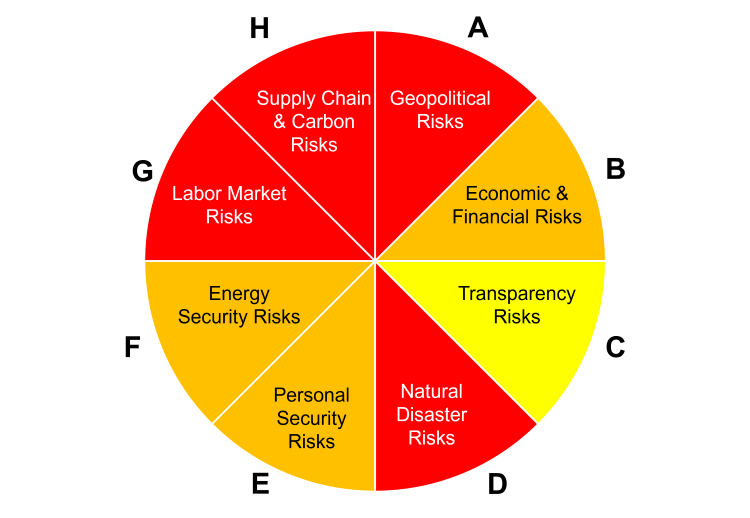

BCI Global has developed a detailed Integral Risk Assessment Method (IRAM) in which 8 risk categories (see visual) with in total 50 risk factors are identified. IRAM can be applied to production plants and distribution centers all over the world and gives per facility a detailed insight in the risks involved and potential mitigation opportunities.

Re-shoring

De-risking the global value chain is for many companies a C-level priority. BCI Global has made a Risk Resilience Framework, distinguishing 5 building blocks: Awareness | Preparedness | Performance | Non-footprint Risk Mitigation Measures | Footprint Adjustments.

The last category includes re-shoring, i.e. less production capacity in China/Asia and more manufacturing activities in major markets like Europe and the US. Research and our daily practice show that reshoring (read: regionalization of production) can be on-shoring (new production operations in most important markets, for example US or Germany) or near-shoring (new production plants near important markets for example Mexico or Poland).

Deciding to change the manufacturing network is a complex decision. With our software tools we help companies to decide which manufacturing footprint scenario scores best on C4 assessment: Costs | Customer impact | Risk Conditions | Carbon.

Interested in how to develop a risk resilient future proof value chain strategy?

Request the thought provoking presentation of BCI Global HERE.