Customers all over the world expect the same for spare parts deliveries: same or next day delivery, products always available, choices for delivery points. And in the US and Europe that is not a problem. But how to deliver spare parts and meet these expectations in Saudi Arabia, Kenya, Nigeria, Iran, South Africa?

A survey of Buck Consultants International shows that in reality the difficulties in emerging markets can be many. Customs inefficiencies (timing, documentation), import restrictions, limited service / geographical coverage and security issues do not match with high customer expectations. To build a customer focused and cost efficient spare parts supply chain, four key building blocks are needed, explains Carlo Peters, principal consultant at Buck Consultants International. “The distribution center network is the starting point. Routing is important as we see more and more direct delivery to the customer from the supplier or plant instead of a distribution center. The third building block is inventory segmentation and planning. Let’s not forget that the vast majority of the spare parts deliveries is for only a limited number of SKUs. The last building block consists of the management and service of transport through various modalities”. With these building blocks each company can optimize their specific spare parts supply chain, keeping service levels high and costs as competitive as possible.

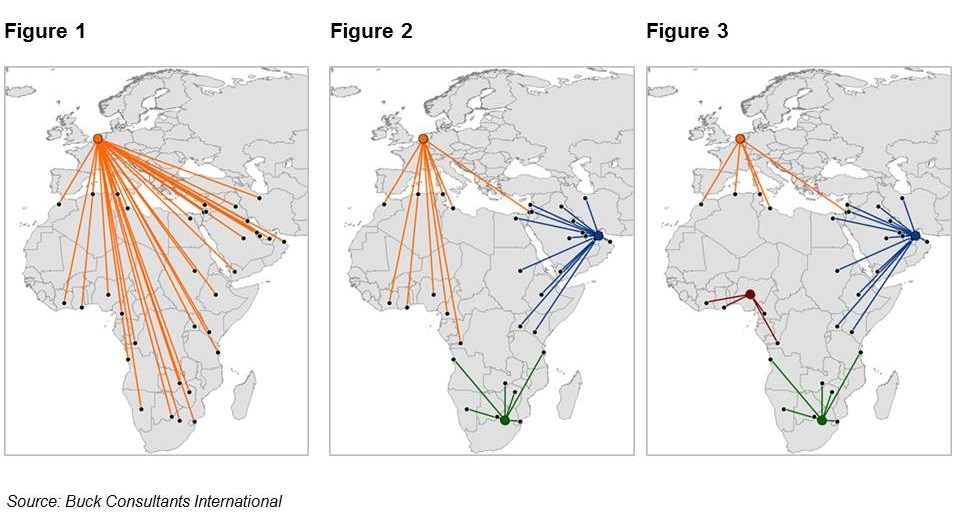

Growth of business in Africa and the Middle East leads to new routes-to-market strategies. Srini Vasudevan, senior consultant at Buck Consultants International, explains the dynamics in spare parts supply chains. “The starting point for many companies is a European spare parts hub serving Middle East and Africa (figure 1). As business expands a company might need over time a regional hub in for example the United Arab Emirates for Middle East and East Africa, and a hub in South Africa to cover the southern part of Africa, while the European hub still services customers in North and West Africa (figure 2). A logical next step could be a regional solution with various hubs in Africa (figure 3). However, due to the lack of seamless customs processes and appropriate infrastructure this is not (yet) feasible. A good alternative is consignment stock of critical spare parts at strategic customers or locations”.