Buck Consultants International (BCI) has hosted a number of interactive sessions on Control Towers (CTs), enabling over 100 Control Tower using participants debated the trends and developments. The most important conclusion has been that although Control Towers have been widely adopted, the step toward an End-to-End Supply Chain scope and the convergence of the physical and digital world (digitalized Supply Chain) still needs to be made by most companies.

A Control Tower according to BCI is “an organization (people) that is overlooking (all) parties in the Supply Chain that has processes in place for daily execution and control with capabilities and (IT) tools that supports operational and strategic decision making with the objective to continuously improve service and bottom-line result”.

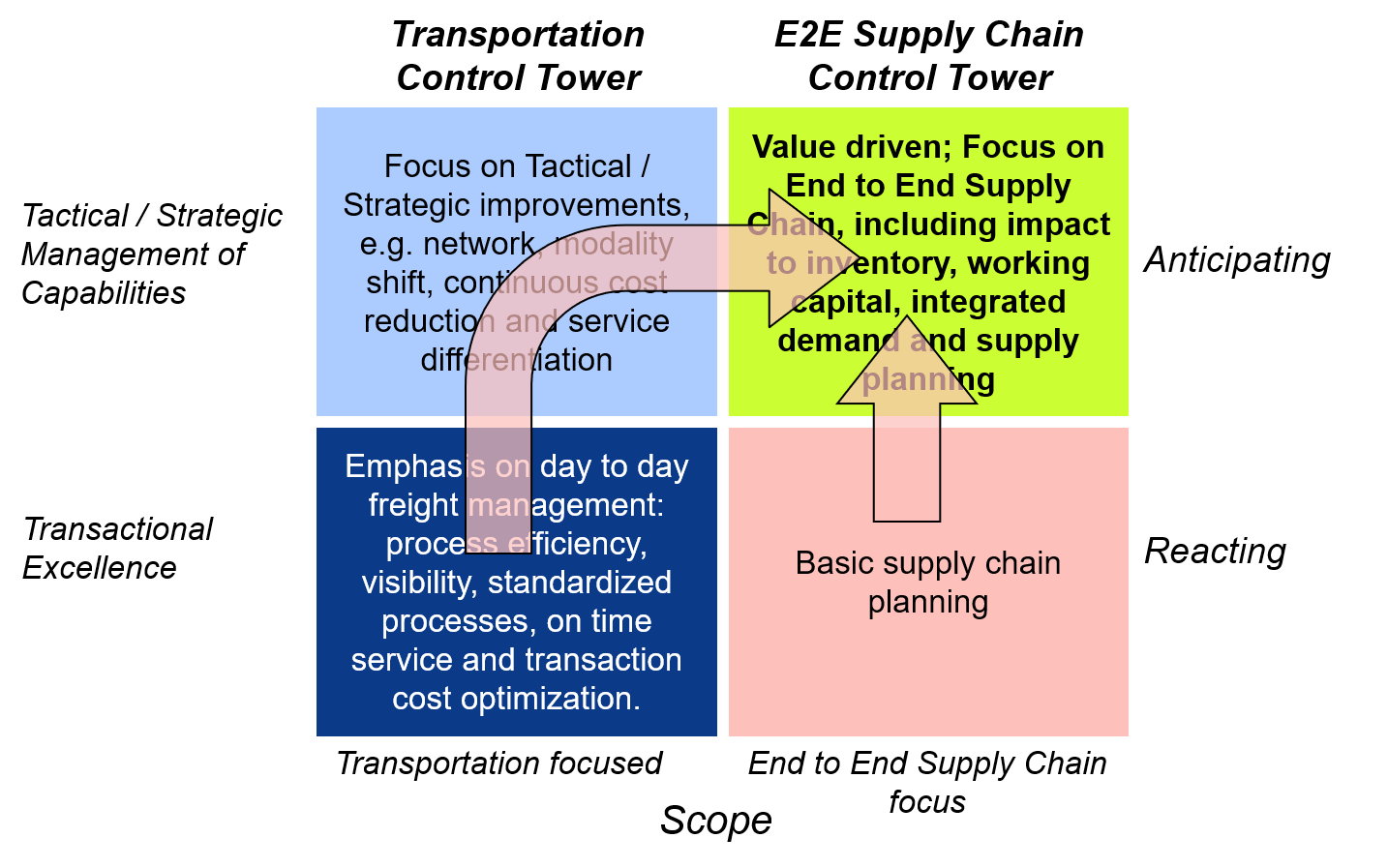

Control Towers have been around for decades and exist in a variety of forms and set-ups. This is mostly driven by the scope and the role of the Control Tower within an organization (global vs regional, one or more transport modes). Currently, most CTs still focus on transport optimization, but the aspiration stated is clearly toward end-to-end solutions.

The benefits achieved most frequently by CT operations are: increased supply chain visibility to improve reliability, decreasing (transportation) costs and continuous improvement. Next to these benefits the creation of an uniform dataset (Single Point of Truth) is growing in importance.

In certain areas the expected benefits do not (completely) materialize yet:

BCI has a developed a Control Tower Maturity Matrix which covers Strategic, Tactical and Operational processes and best practices. This Maturity Matrix supports benchmarking and can identify a path forward.

Top 5 critical success factors to implement a Control Tower are:

An important question is whether to in- or outsource Control Tower operations to a 4th Party Logistics Provider (4PL)? Outsourcing is most beneficial in areas where the company lacks the experience and can leverage of a 4PL’s existing capabilities in the related geographies and requested services. Size and scale are factors that will drive the decision to either insource or outsource the control tower activities as well. In the past the entry barrier for brand owners to implement a control tower was high. Given technology developments and SAAS models this entry barrier has been lowered substantially.

Next to that a 4PL set-up does not equal 3PL operations; BCI advises to separate 4PL from 3PL activities. A 4PL should be independent.

The scope of Freight Control Towers is expanding and more and more End-2-End Supply Chain operations arise.

Source: BCI

Difference with “regular” Control Tower operations is an increased focus on tactical/strategic capabilities and covering more elements of the supply chain, such as supply chain redesign, end-to-end inventory planning and integrated demand & supply planning.

Examples of companies that made the transition towards an End-to-End Control Tower are Samsung, Apple, Amazon, Walmart and Unilever. Achieving benefits like improved customer service, lower inventory and operational costs.

To enable an End-to-End supply chain puts high requirements on the technology used and the systems available. There is a clear tendency towards convergence of the physical and the digital world. Process automation (RPA), data analytics (big data/Artificial Intelligence) and automated planning (lights-off planning/no-touch supply chains) are elements of the extensive connections that are developed between the physical and digital world.

Moving towards a digitalized supply chain will create challenges. Not only related to the IT systems and partners used, but especially towards the company’s employees. Workforce transformation will cause existing jobs to disappear or to change considerably (e.g. supply chain planners) whereas new roles will emerge (e.g. data scientists). A final consideration is that moving towards a digitalized supply chain will require a solid and extensive change management organization.

Concluding: an End to End Control Tower function can act as a solid base to digitize your supply chain incorporating the world of the physical logistics and planning and the expectation is that Control Towers will eventually evolve into digital supply chains over time. Where will you start your journey?

For more information call at +31-24-3790222 or email:

Carlo Peters, Principal Consultant carlo.peters@bciglobal.com

Robert Wieggers, Senior Consultant robert.wieggers@bciglobal.com